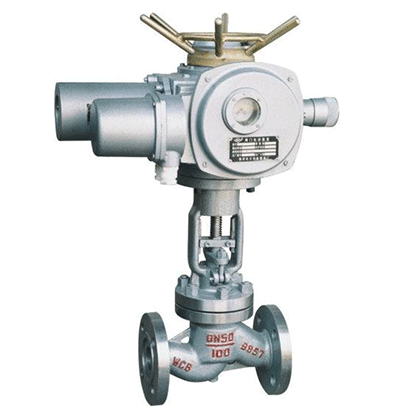

Home > Product > Globe Valve

Working principle and purpose of the product:

The electric globe valve complies with advanced domestic and international standards such as GB, JB, ANSI, JSI, BS, DIN GB12235 and American standard ANSI B16.34. It has a reasonable structure, reliable sealing, good performance, and beautiful appearance. Flange connected steel globe valves are suitable for cutting off or connecting pipeline media in various working conditions such as petroleum, chemical, pharmaceutical, fertilizer, and power industries with nominal pressure of 1.6Mpa~16.0Mpa and working temperature of -29~550 ℃.

Product performance characteristics:

The valve is designed and manufactured in accordance with the national standard GB12235, with a reasonable structure, reliable sealing, excellent performance, and beautiful appearance.

2. The sealing surface of the valve disc and seat is made of iron-based alloy or Stellite drill based hard welding, which is wear-resistant, high-temperature resistant, corrosion-resistant, scratch resistant, and has a long service life.

3. The valve stem has undergone quenching and surface nitriding treatment, providing excellent corrosion resistance and abrasion resistance.

4. Various piping flange standards and flange sealing surface types can be adopted to meet various engineering needs and user requirements.

5. The valve body material variety is complete, and the packing and gasket can be reasonably selected according to actual working conditions or user requirements, which can be applicable to various pressure, temperature, and medium working conditions.

6. The reverse seal is made by connecting the sealing seat with threads or welding austenitic stainless steel on the body, ensuring reliable sealing. The replacement of the packing can be carried out conveniently and quickly without stopping the machine, without affecting the operation of the system.